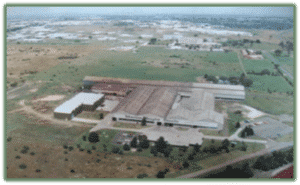

iEnvi Principal Michael Nicholls directed and managed a soil and groundwater assessment and soil and groundwater hexcavalent chromium (Cr6+) remediation, both on and offsite, at a steel processing factory.

The industrial site had operated for over 50 years and contained corroded drainage pits, corroded pipelines, leakage into stormwater drains, corroded stormwater pipes, and corroded drip trays that allowed chromic acid to migrate through the clay and weathered basalt vadose zone into a fractured basalt aquifer, approximately 450m to the south of the site, with an estimated 35,000m3 of hydrocarbons and hexavalent chromium impacted soil, and 1,260,000m3 of impacted groundwater affecting dozens of private properties to the south of the site.

A community liaison plan was developed and implemented, and after all primary sources were controlled or removed pilot trials began including soil treated by a polylactate polymer and a benign organosulfur compound, allowing for controlled release of its active components for the long-term. Cr VI was directly precipitated as a hydroxide.

In situ chemical reduction, fractured basalt aquifer, hexavalent chromium, steel works remediation

The hydroxide solids were stable under the low redox potential and oxidising conditions. Cr 6+ was directly precipitated as a hydroxide. The hydroxide solids were stable under the low redox potential and oxidising conditions.

Groundwater was treated by zero-valent iron plus carbon (electron donor) mix. A sulfur component was added to facilitate the biotic reactions. The results of a recent pilot trial demonstrated remediation was effective in reducing hexavalent chromium concentrations from concentrations of up to 96mg/L to <0.002 mg/L, however, the cost was prohibitive.

ISCR is involved in the injection of emulsified soybean oil and sodium persulfate and subsequent performance monitoring, where negatively charged (to prevent coalescence) micro-droplets were injected and transported through the pore spaces and adhered to the sediment, providing a carbon source to the anaerobic bacteria required for the reduction process of Cr6+ to Cr3+ transformation, supplying carbon for a period of 3 to 5 years.

For advice on contamination at your industrial site, contact [email protected]