You see lots of building developments going up, and large construction sites. When developers clear the site and make the soil level or dig holes for footings or basement carparks - where does all that soil go?

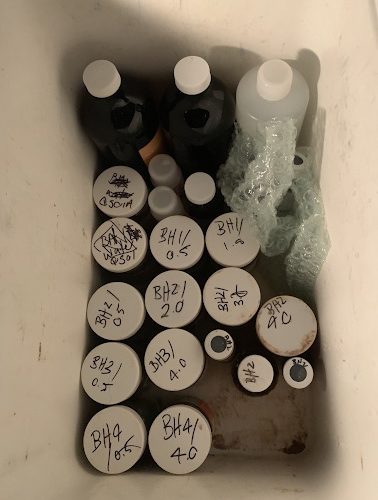

Generally, the soil is treated as waste in order to get it offsite quickly. Sometimes it has historical industrial waste mixed with it (asbestos, gasworks waste, coke, slag, metals, hydrocarbons). You need to classify the soil into a waste category before knowing how much it will cost. That is done by sampling it and comparing it to relevant state waste classification guidelines.

That step is extremely important and can be a significant cost consideration in a development/construction project. It can also cause delays and management and regulatory issues during your already time-poor project.

Soil management during developments is a significant factor for developers with large implications for cost, timeframes and sustainability. A little knowledge of each state's waste, exemption and environmental regulations and approvals is essential.

In addition to soil, groundwater entering large excavations needs to be dewatered, sometimes treated, and get approvals for discharge to help manage it. That can also be a tricky business and a thorough knowledge of waste guidelines and exemptions, and approval processes are essential to minimising the cost and minimising delays during your project.

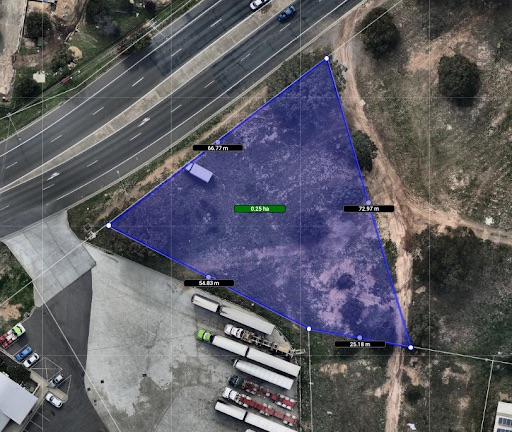

An example of this is if you are a developer and need to excavate a 50 m x 40 m x 10 m deep level basement car park - that will be 20,000 m3 of soil to manage.

Often in particular around city areas, there is historical fill impacted with old industrial waste and the soil requires testing a waste classification to determine where it can go. Furthermore, stockpiling and then testing soil and waiting for laboratory results can take 1 week, and development/construction sites never have the available space. The required truck movements for a truckload of 20, 000 m3 (excavated this is maybe 25,000 m3 or more, and may be equivalent to 40,000 tonnes or more of soil) may be in the hundreds of truck movements, which is not sustainable and leads to congestion and traffic management issues to overcome.

Furthermore, disposal of soil as waste to landfill (the easiest but most expensive option) is not sustainable. In many states contaminated soil may cost $400 per tonne or more to transport and dispose to a landfill including government levies.

Think for a second, for our 50 m x 40 m x 10 m deep level basement car park - that will be 20,000 m3 = about 40,000 tonnes, if all of that had historical contamination and the waste category landfill disposal and transport cost was $400/tonne, the total cost would be $16M in soil disposal costs alone.

Sending soil to landfill is also not a preferred strategy in each state EPA Waste Hierarchies as it results in a contaminated landfill to later manage and emissions and additional transport risks with truck movements. Most EPA bodies prefer avoidance, reuse or treatment where possible. Most developers' budgets prefer that also.

iEnvi Advice

Characterising your waste early is key to having time to select cost-effective solutions. iEnvi has a team that specialises in waste reuse and management to provide more sustainable and cost-effective innovative solutions for how you manage your soil and excavate waste and wastewater.

We can help you look at retaining some soils for landscaping, onsite containment cells, subdividing lots with containment cells so that your site is unimpaired, and sorting and treating soil so that waste categorisation is reduced in level to significantly reduce the cost.

We also help navigate all the 'hidden' exemptions and approvals for your waste soil and water, so that your project will run smoothly and at considerably lower cost and disruption.

Useful Links:

NSW:

Waste Classification Guidelines

Existing Resource Recovery Orders

General Immobilisation Approvals

QLD:

Waste Classification Guidelines

VIC:

How to Manage Industrial Waste

Reuse of PIW - direct and secondary beneficial reuse

SA:

Resource recovery policy (2010)

iEnvi Website Related Links:

RECENT POSTS

Environmental Delineation Investigation at Industrial Site in Northwest Sydney

Project Overview: iEnvironmental Australia (iEnvi) conducted a Delineation Investigation (DI) at anindustrial site located in the northwest of Sydney, following...

Compliance Investigation &Cost-Effective Remediation and Beneficial Reuse of Asbestos-Impacted Soil at Industrial Site in Victoria

The Victorian EPA requested an investigation at an industrial site in Coolaroo to meet General Environmental Duty requirements. iEnvironmental Australia...

The Role of Environmental Consultants in Contaminated Land Management

The Crucial Role of Environmental Consultants in Contaminated Land Management Environmental consultants are key in managing Australia's growing concern over...

Key Strategies for Effective Soil and Groundwater Remediation

Effective Soil Remediation Techniques Effective soil and groundwater remediation strategies are essential for safeguarding human health and the environment, especially...

Understanding Preliminary Site Investigations: A Guide for Property Transactions

Demystifying Preliminary Site Investigations: A Comprehensive Guide for Property Transactions Understanding the role of Preliminary Site Investigations (PSI) in environmental...

Innovative Strategies for Contaminated Site Remediation and Validation

To ensure environmental sustainability and compliance, effective environmental risk assessments are indispensable for organizations in Australia, especially those in high-impact...

Essential Steps in Conducting Effective Environmental Risk Assessments

Step-by-Step Guide to Conducting Effective Environmental Risk Assessments To ensure environmental sustainability and compliance, effective environmental risk assessments are indispensable...

Strategies for Managing Environmental Liabilities in Business

Environmental stewardship is a critical aspect of corporate responsibility in business operations. Discover how to turn your company's environmental challenges...

Understanding the Role of Environmental Engineers in Contamination Control

Environmental Engineers and Their Role in Contamination Control Environmental engineers are key to controlling contamination and protecting our environment. Discover...

The Evolving Landscape of Environmental Consulting in Australia

The Evolving Landscape of Environmental Consulting in Australia Australia's environmental consulting sector is experiencing a major shift. Discover how innovations...

The Future of Environmental Assessment: Trends and Predictions

Environmental assessment is at a critical juncture, facing transformative changes as it addresses escalating environmental challenges. Discover how the future...

Best Practices in Waste Soil and Water Management for Compliance

Discover the essential practices for managing waste, soil, and water to comply with regulations and support environmental sustainability. Unlock the...

Conceptual Site Models: A Tool for Understanding Contamination

Understanding site contamination in environmental management necessitates a comprehensive strategy. Unlock the secrets to battling site contamination with Conceptual Site...

Innovative Approaches to Environmental Consulting in Australia

Innovative Environmental Consulting Services for Australian Businesses iEnvironmental Australia Pty Ltd (iEnvi) leads the way in innovative environmental consulting across...

The Business Benefits of Environmental Integrity and Sustainability

Financial Benefits of Environmental Integrity and Sustainability Environmental integrity and sustainability yield significant business advantages. Unlock the secret to boosting...

Collaborative Solutions in Environmental Consulting: Case Studies

This article explores collaborative solutions in environmental consulting, highlighting the necessity and impact of partnership in achieving sustainable results. Discover...

The Importance of Quality Plans in Environmental Sampling and Analysis

Quality plans are essential in environmental sampling and analysis to protect ecosystems and ensure data integrity. Ever wondered how we...

Leveraging Environmental Engineering for Sustainable Business Practices

Environmental engineering enhances sustainable business practices, transforming them from ethical choices to strategic imperatives. Discover how embracing environmental engineering can...

Navigating Environmental Compliance: Essential Tips for Australian Businesses

Environmental Compliance: A Guide for Australian Businesses Australian businesses must embrace sustainable practices to meet ethical and legal obligations in...

Advanced Techniques in Soil and Water Contamination Management

Innovative solutions and strategies for managing soil and water contamination are explored by iEnvironmental Australia, addressing a critical issue in...

Environmental Due Diligence in Property Transactions: A Comprehensive Approach

Environmental due diligence in property transactions ensures sustainable investment by identifying and managing potential environmental liabilities. Unlock the secret to...

The Impact of Environmental Regulations on Australian Businesses

Environmental Regulations and Australian Businesses: A Comprehensive Overview Environmental regulations significantly influence how businesses operate in Australia. Ever wondered how...

Overcoming Challenges in Environmental Project Management

Navigating the complexities of environmental project management requires a deep understanding of its challenges, including regulatory compliance, stakeholder engagement, and...

Expert Legal Advice for Environmental Cases: A Business Perspective

Understanding the Legal Landscape of Environmental Compliance Navigating the legal intricacies of environmental compliance is essential for businesses in today's...